Infrared Thermography

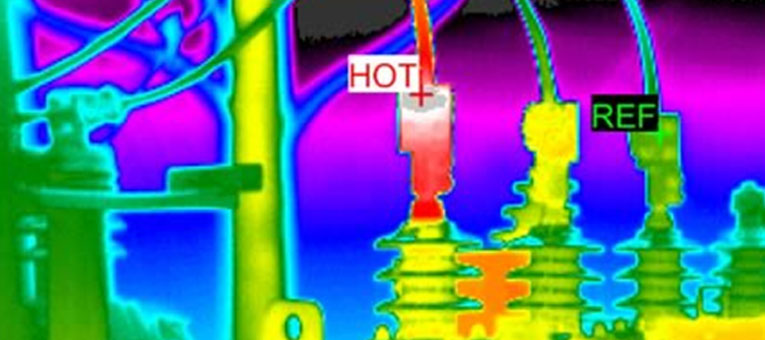

Infrared Thermography can be used to analyse and determine thermal anomalies. These anomalies may be caused by poor lubrication, excessive loads, misalignment and worn components. It can also be used for investigating and monitoring electrical problems.

It is a non-intrusive monitoring technique.

Infrared Thermography is based on measuring heat from a surface and converting this to a temperature map. Different temperatures are indicated by different colours or shades of grey.

Possible benefits of thermography are:

- A proactive, non-contact and non-invasive inspection technique, which is often well suited as part of a predictive maintenance programme

- An easier, faster and safer method of early fault condition detection

- Inspection, over time, of equipment under same running conditions, allowing thermal anomalies to be easily detected

- Inspection of running equipment under full load, minimising production interference

- Inspection of difficult to access live electrical equipment

- Reduction of production losses due to unplanned downtime, resulting in increased productivity and profitability

- Reduction of time necessary for planned shutdown

- Reduction of maintenance and repair costs

- Increased equipment lifetime and mean time between failures (MTBF)

- Increased availability and reliability of plant