SAVE UP TO 60% ON A CAT® CERTIFIED POWER TRAIN REBUILD

The heart of any piece of equipment is the power train. A Cat Certified Power Train Rebuild is a cost-effective way to maximise the multiple lives that are designed in to a Cat® machine, during the rebuild all components are inspected, repaired and overhauled and the required product updates carried out.

A rebuild enables you to restore like-new performance, incorporate critical engineering improvements, enhancements and technology updates on your machine, while also being able to bring a machine to current production status and safety standards with additional features that may not have been previously available on the machine.

Want even higher levels of performance and fuel efficiency at a much lower price than buying new? Upgrade or retrofit your power train and machine with new features, technologies and safety options available on today’s models. It’s an affordable way to enhance your power train even further while it’s already in the shop for a rebuild with no additional downtime required.

Why Choose a Power train rebuild?

- Restores power train to like-new performance

- Covers radiator, engine, transmission, torque converter, final drive and axle

- All components disassembled. All critical engineering updates incorporated*

- Genuine Cat parts

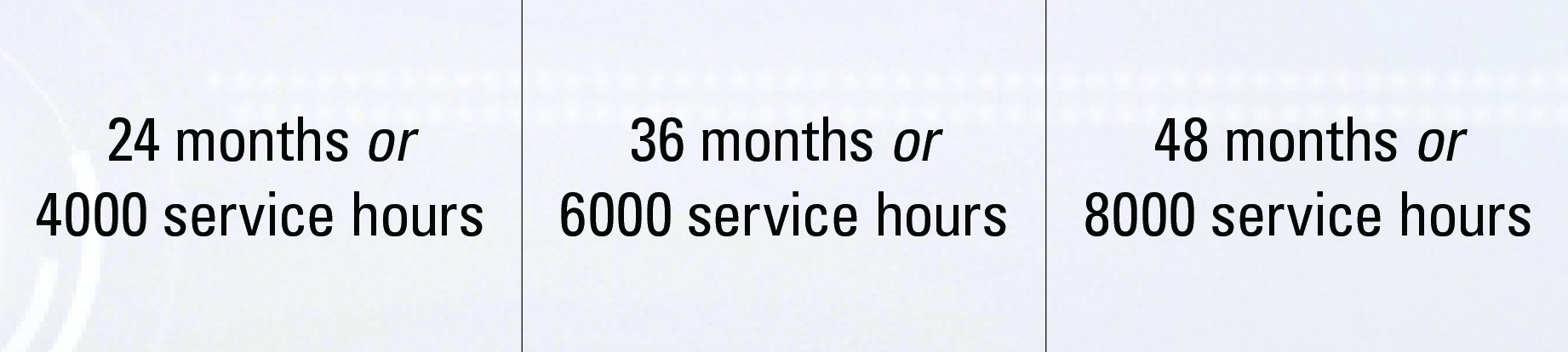

- Extended coverage available

*Your rebuilt power train will generate information you can use to boost productivity, reduce costs and manage risks. Cat Product Link is standard equipment on all Cat Certified Power Train Rebuilds.