Enquire about "Cat® C32 Industrial Power Unit" Now

Industrial Diesel Power Units - Highly Regulated

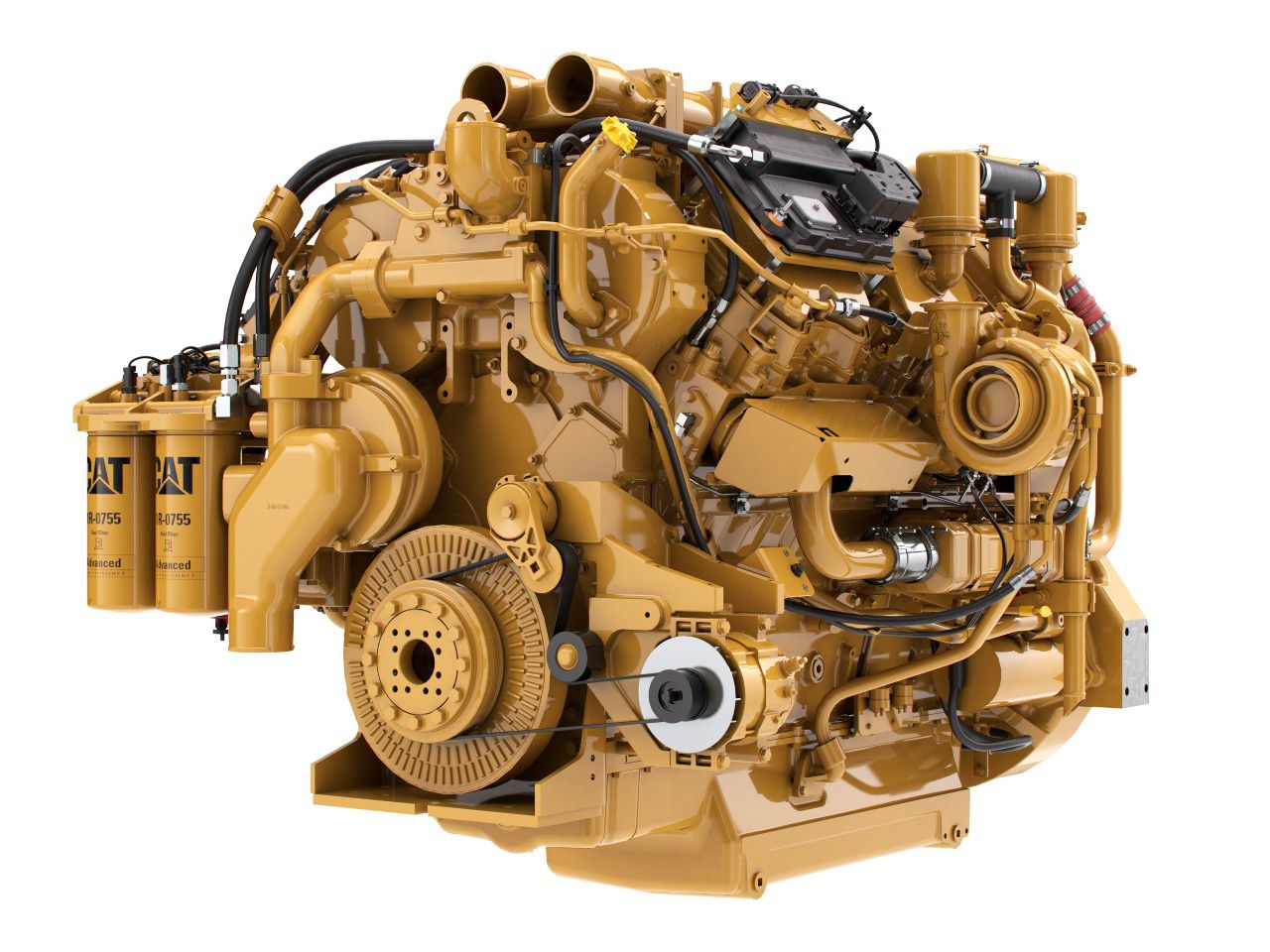

Cat® C32 Industrial Power Unit

Installation

When it comes to making the engine installation process smoother, look to the Cat C32. Using innovative technology solutions, the C32 eliminates the need for diesel exhaust fluid (DEF) and reduces the size of the overall engine package. The DOC-only aftertreatment does not require regeneration and is maintenance free until a major engine overhaul.

Fully configurable engine with exceptional power density, a cooling package designed and backed by Caterpillar, plus a simplified engine mounted aftertreatment all help minimize total package size, simplify installation, and provide you with the quality deserve.

Ideal Applications

The C32 is ideal for any application that requires large amounts of dependable power and torque. Applications include:

- Bore/drill rigs

- Chippers/grinders

- Cranes

- Dredges

- Forestry

- General industrial

- Hydraulic power units

- Irrigation equipment

- Material handling

- Mobile earthmoving equipment

- Paving equipment

- Pumps

- Rock crushers

- Shovels/draglines

- Shredders

- Snow blowers

- Surface hauling equipment

- Trenchers

Total Cost of Ownership

The maintenance-free DOC aftertreatment simplifies service and helps reduce cost. The DOC aftertreatment guarantees DEF-free operation. That’s savings you can measure every day.

500 hour standard service intervals and the ability to extend them using the S•O•S program allows you to optimize oil change intervals and minimize operating expenses. See your Cat dealer for details.

Cat Dealer Product Support

World-classs product support offered through the Cat dealer network. Your Cat dealer can provide scheduled maintenance, including S•O•S sampling.

Customer support agreements (CSA) and extended service coverage (ESC) help reduce costs and ensure you machine is serviced on schedule. See your Cat dealer for details.

| Power Rating | |

|---|---|

| Maximum Power | 746 kW (1000 hp) |

| Maximum Torque | 5186 Nm @ 1200 rpm (3825 lb-ft @ 1200 rpm) |

| Rated Speed | 1800 rpm |

| Minimum Power | 746 kW (1000 hp) |

| Emission Standards | |

|---|---|

| Emissions | U.S. EPA Tier 4 Final and EU Stage V |

| General | |

|---|---|

| Engine Configuration | V-12 |

| Cycle | 4 |

| Bore | 145 mm (5.7 in) |

| Stroke | 162 mm (6.4 in) |

| Displacement | 32.1 l (1958.9 inu00b3) |

| Compression Ratio | 16.0:1 |

| Aspiration | Twin Turbocharged Aftercooled (TTA) |

| Combustion System | Direct Injection |

| Cooling System | liquid |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC |

| Power Unit Dimensions | |

|---|---|

| Height | 1970 mm (77.6 in) |

| Length | 2558 mm (100.7 in) |

| Width | 1637 mm (64.4 in) |

Standard Equipment

- Air Inlet System

- Turbocharged

- Air-to-Air Aftercooled

- Control System

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

- Cooling System

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Water pump, inlet

- Exhaust System

- Exhaust manifold, dry

- Optional exhaust outlet

- Flywheels and Flywheel Housing

- Choice of SAE No. 0 or SAE No. 1 flywheel housing

- Fuel System

- MEUI injection

- Fuel filter, secondary (2 micron)

- Electronic fuel priming

- Lube System

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Rear sump oil pan

- Oil dipstick

- Gear driven oil pump