Enquire about "Cat® C3.6 Diesel Engine" Now

Industrial Diesel Engines - Highly Regulated

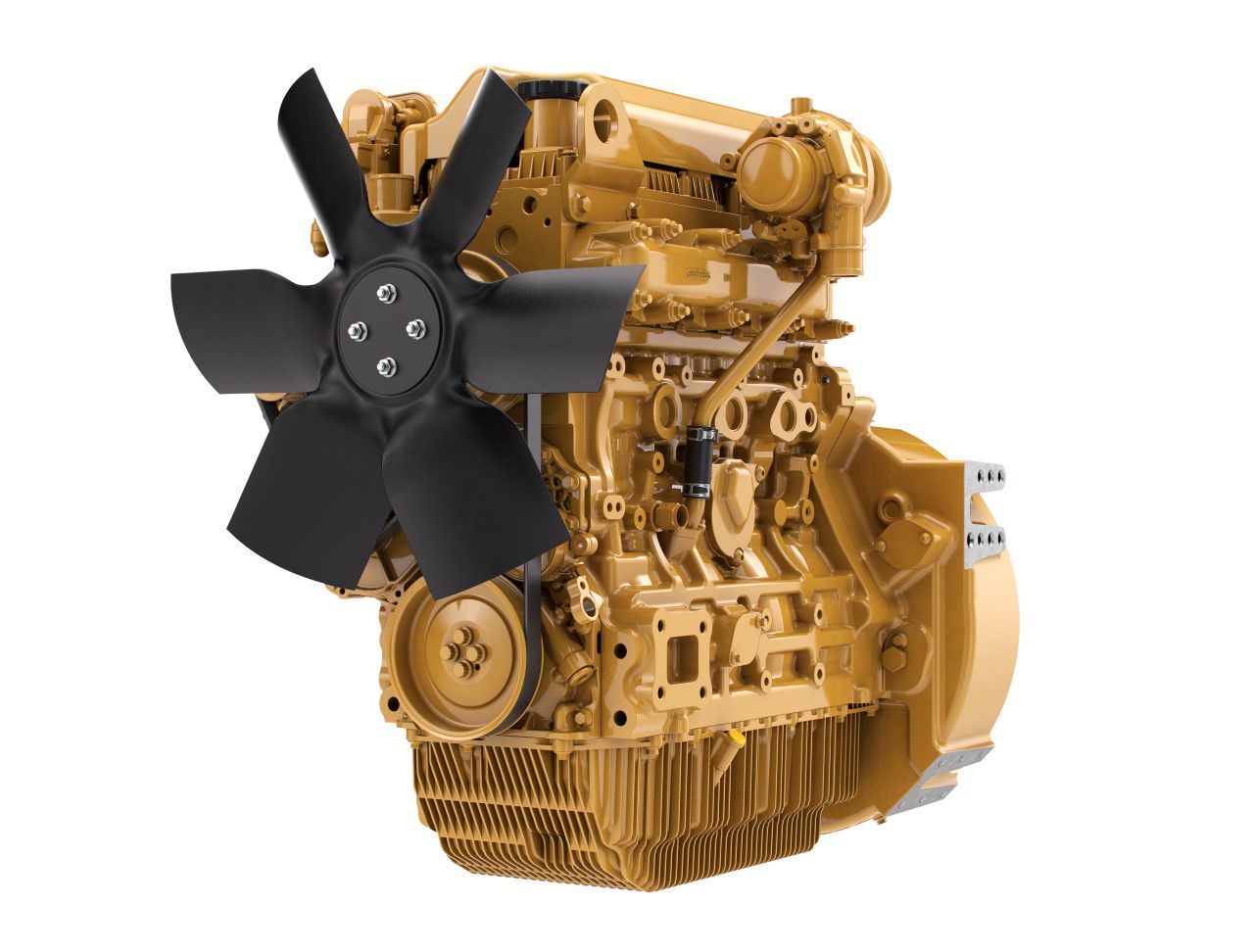

Cat® C3.6 Diesel Engine

Installation

Smaller in size than it’s predecessor, the Cat C3.6 is a powerful engine in a compact and easily integrated size that saves OEMs valuable time and costs. With flexible aftertreatment mounting options and a simplfied engine installation process, the C3.6 can be placed into a wide variety of applications with agility and speed.

Advanced Features

What would you do with 5% more power density and 12% more torque? The C3.6 uses the latest in technology to bring OEMs the most efficient and powerful engine—even at peak performance—when compared to the previous engine model.

Broad Application Range

The Cat® C3.6 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards

Ideal for industrial, agricultural and construction applications such as:

• Excavators

• Pumps

• Compressors

• Chippers

• Grinders

• Asphalt paving equipment

• Hydraulic power unit

• Bore rigs

• Drill rigs

• Tractors

• Telehandlers

Total Cost of Ownership

Owning and operating equipment is a big investment, so it only makes sense to get the most you can from it. Thanks to the chosen technologies of the Cat C3.6, owners can experience an overall savings in fluid.

Cat Dealer Product Support

Backed by a five-year warranty, the Cat C3.6 is also supported by Caterpillar’s unmatched Dealer Support Network with over 171 locations in 192 countries across the world—so the expert assistance you need is always close by.

Safety

Safety on the job site matters. The Cat C3.6 is 3 decibles quieter output than the previous engine equivalent, meaning less noise from the engine and a more alert and attentive operator.

| Power Rating | |

|---|---|

| Maximum Power | 100 kW (134 hp) |

| Maximum Torque | 550 Nm @ 1500 rpm (406 lb-ft @ 1500 rpm) |

| Rated Speed | 2000-2400 rpm |

| Minimum Power | 55 kW (74 hp) |

| Emission Standards | |

|---|---|

| Emissions | U.S. EPA & CARB Tier 4 Final, EU Stage V |

| General | |

|---|---|

| Engine Configuration | In-Line 4 |

| Bore | 98 mm (3.9 in) |

| Stroke | 120 mm (4.7 in) |

| Displacement | 3.6 l (220 inu00b3) |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged-Aftercooled (TA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC+DPF or DOC+DPF+SCR |

| Engine Dimensions - Approximate | |

|---|---|

| Length | 667 mm (26.3 in) |

| Width | 564 mm (22.2 in) |

| Height | 787 mm (31 in) |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 381 kg (840 lb) |

Standard Equipment

- Control System

- Starter motor (12V or 24V)

- Alternator (12V or 24V)

- Electronic Control Unit (chassis mounted)

- Engine control sensors and robust wiring harness

- Data interface via CANbus J1939

- Flywheels and Flywheel Housing

- Flywheel housings – SAE 3 or SAE 4

- Choice of flywheel to match industry common hydraulic pumps and transmissions

- Side PTO with SAE A or SAE B interface

- Fuel System

- Fuel filter – preconnected but chassis mounted

- With water sensor

- Lube System

- Lubricating oil filters

- High incline oil pan – 35° continuous in all directions

- General

- Cold start capability to -20° C (-4° F) with standard equipment

- Paint: Caterpillar yellow, with optional colors available at request

- U.S. EPA Tier 4 Final, EU Stage V Aftertreatment/ Clean Emissions Control Equipment

- Diesel Oxidation Catalyst (DOC)

- Selective Catalytic Reduction (SCR)

- SCR Auxiliaries