Enquire about "C4.4 Generator Set" Now

C4.4 Generator Set

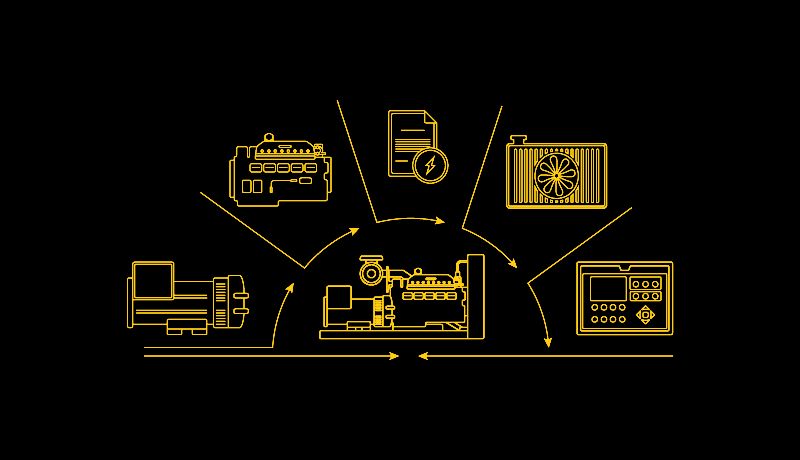

Cat Generator Set Package

- Cat generator set packages have been fully prototype tested

- Accepts 100% block load in one step and meets NFPA 110 loading requirements

- Conform to ISO 8528-5 steady state and transient response requirements

Cat Diesel Engine

- Reliable, rugged, durable design

- Field-proven in thousands of applications worldwide

- Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight

F-Frame Alternator

- Superior motor starting capability minimizes need for oversizing alternator

- Designed to match performance and output characteristics of Cat diesel engines

- Robust Class H insulation

GCCP 1.2 Control Panel

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

- Image may not be a representative of actual product

Cooling System

- Designed to operate in standard ambient temperatures up to 55°C (131°F)

- Contact your Cat Dealer for specific ambient and altitude capabilities

Certifications

Cat dealers provide extensive post-sale support including maintenance and repair agreements. Cat dealers have over 1,800 dealer branch stores operating in 200 countries. The Caterpillar S•O•S℠ program cost effectively detects internal engine component condition, even the presence of unwanted fluids and combustion by-products

One Safe Source

- Components used in the generator set are selected based on seamless design integration to provide the optimum performance

- The generator set is fully assembled at a Caterpillar facility following our quality guidelines

- Each generator set package is tested before leaving the Caterpillar facility

- Cat product support, including dealer service, parts and warranty covers the entire Cat power system

World Wide Product Support

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

| Generator Set Specifications | |

|---|---|

| Maximum Rating | 60 ekW |

| Minimum Rating | 36 ekW |

| Emissions/Fuel Strategy | U.S. EPA Cert., Tier 3 |

| Voltage | 208 to 600 Volts |

| Frequency | 60 Hz |

| Speed | 1800 rpm |

| Duty Cycle | Standby, Prime |

| Engine Specifications | |

|---|---|

| Engine Model | C4.4, In-line 4, 4-cycle diesel |

| Bore | 105 mm (4.13 in) |

| Stroke | 127 mm (5 in) |

| Displacement | 4.4 l (268.5 in) |

| Compression Ratio | 18.2:1 |

| Aspiration | Turbocharged |

| Fuel System | Electronic (adjustable) |

| Governor Type | Adem™A4 |

| Generator Set Dimensions | |

|---|---|

| Length - Maximum | 1925 mm (75.8 in) |

| Width - Maximum | 1120 mm (44.1 in) |

| Height - Maximum | 1361 mm (53.6 in) |

Standard Equipment

- Certificates

- IBC seismic and wind Certifications

- Charging System

- NFPA battery charger UL10A 120VAC

- Air Inlet System

- Air cleaner

- Cartridge type air filter

- Circuit breakers

- Second circuit breaker box

- 3-Pole 100% rated

- Power terminal strip

- Breakers (100% UL rated)

- Control Panel

- 1000028996

- Exhaust System

- Stub pipe, gaskets, raincap and SAE exhaust flange for customer use – shipped loose

- Fuel System

- Standard open set fuel tank/base supplied base, formed steel with single wall integral 8-hour fuel tank

- Cooling System

- Coolant drain line with valve

- Radiator and cooling fan with guards

- Fan drive, battery charging alternator drive

- Caterpillar extended life coolant

- Radiator stone guard

- Generator

- 12 Leads

- Governing System

- Mechanical and electrical governing system – model dependent

- Lube System

- Oil drain line with valve

- Lubricating oil

- Control Panels

- WCA1 Low coolant temperature alarm

- WSS1 Low coolant level shut down

- FSS Low fuel level alarm & indication panel circuitry required when sub-base tank is selected

- NFPA110 bundle includes:

- PAA1 Panel mounted audible alarm

- A Coolant heater, remote annunciator or 0.8 power factor test may be required depending on the application

- Oil temperature gauge and sender

- PBC10NU NFPA battery charger

- Ground fault relay

- Discrete I/O module

- Volt free contacts genset run and common alarm

- Audible alarm

- Remote E-stop button

- Remote annunciator module

- Low coolant temperature alarm

- Protective devices:

- Overload shutdown via breaker

- Fuel level reading

- Low coolant level shutdown

- General

- Engine and alternator pre-paint, Caterpillar yellow

- Starting/Charging System

- 24V battery with rack and cables

- Batteries

Optional Equipment

- Certificates

- IBC seismic and wind Certifications

- Alternator System

- R Frame auxilliary winding

- Air Inlet System

- Cartridge type air filter

- Charging System

- NFPA battery charger UL10A 120VAC

- Circuit breakers

- 3-Pole 100% rated

- Breakers (100% UL rated)

- Second circuit breaker box

- Power terminal strip

- Control Panels

- Discrete I/O module

- Remote annunciator module

- Remote E-stop button

- Protective devices: Low coolant temperature alarm – Low coolant level shutdown – Fuel level reading – Overload shutdown via breaker

- Ground fault relay

- Audible alarm

- Oil temperature gauge and sender

- Volt free contacts genset run and common alarm

- NFPA110 bundle includes: FSS Low fuel level alarm & indication panel circuitry required

when sub-base tank is selected – WSS1 Low coolant level shut down – WCA1 Low coolant temperature alarm – PAA1 Panel mounted audible alarm – PBC10NU NFPA battery charger – A Coolant heater ,remote annunciator or 0.8 power factor test may be required depending on the application

- Heating Elements

- Coolant heater

- Battery heater

- Anti-condensation heater

- Lube oil sump heater

- Jacket water heater

- Wiring for canopy space heater

- Cooling System

- Radiator transition flange

- Enclosures

- Panel viewing window

- External emergency stop

- Sound attenuated enclosure, Level 2

- Weatherproof enclosure

- Sound attenuated enclosure, Level 1

- Fuel System

- 5 Gallon fill containment

- Tank riser

- 209 and 394 gallon sub-base fuel tanks

- Emergency vent pipe

- 5 Gallon spill containment

- Mounting System

- Seismic vibration isolators

- Tests

- Generator test report

- PGS Test report @ 0.8 power factor

- 4 Hour factory test

- PGS Test report @ 1.0 power factor

- Exhaust System

- 10, 25 and 35 dBA silencer systems

- Overhead silencer mounting kit

- Generators

- Permanent magnet excitation (PMG) generator