Enquire about "C32 Generator Set" Now

C32 Generator Set

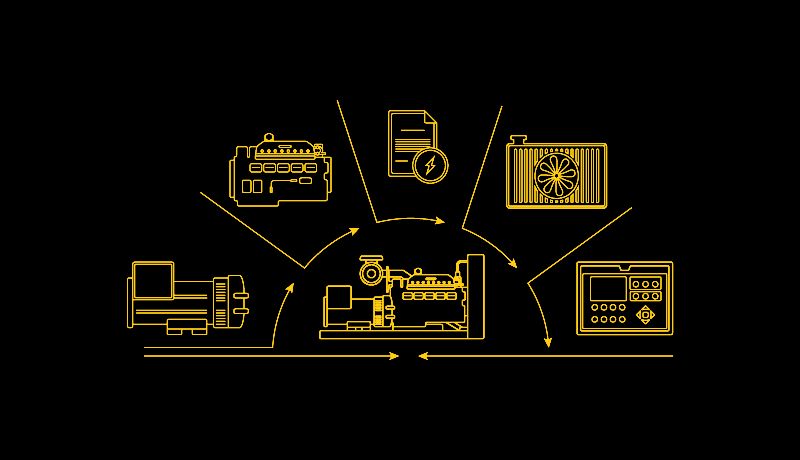

Cat Generator Set Package

- Cat generator set packages have been fully prototype tested

- Accepts 100% block load in one step and meets NFPA 110 loading requirements

- Conform to ISO 8528-5 steady state and transient response requirements

Cat Diesel Engine

- Reliable, rugged, durable design

- Field-proven in thousands of applications worldwide

- Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight

SR5 Alternator

- Superior motor starting capability minimizes need for oversizing alternator

- Designed to match performance and output characteristics of Cat diesel engines

- Robust Class H insulation

EMCP 4 Control Panel

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

Cooling System

- Designed to operate in standard ambient temperatures up to 50°C (122°F)

- Contact your Cat Dealer for specific ambient and altitude capabilities

Certifications

- UL 2200 Listed

- CSA

- IBC seismic certification

- OSHPD pre-approval

One Safe Source

- Components used in the generator set are selected at the design stage to provide optimum package performance

- The generator set is fully assembled at a Caterpillar facility following our quality guidelines

- Each generator set package is tested before leaving the Caterpillar facility

- Cat product support, including dealer service, parts and warranty covers the entire Cat power system

Worldwide Product Support

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

| Generator Set Specifications | |

|---|---|

| Maximum Rating | 1250 ekW |

| Minimum Rating | 830 ekW |

| Emissions/Fuel Strategy | Low Fuel, Tier 2 Nonroad Stds |

| Voltage | 220 to 4160 Volts |

| Frequency | 60 Hz |

| Speed | 1800 rpm |

| Duty Cycle | Standby, Mission Critical, Prime, Continuous |

| Engine Specifications | |

|---|---|

| Engine Model | C32 TA, V-12, 4-Stroke Water-Cooled Diesel |

| Bore | 145 mm (5.71 in) |

| Stroke | 162 mm (6.38 in) |

| Displacement | 32.1 l (1958.86 inu00b3) |

| Compression Ratio | 15.0:1 |

| Aspiration | TA |

| Fuel System | MEUI |

| Governor Type | Adem™A4 |

| Generator Set Dimensions | |

|---|---|

| Length - Minimum | 4165 mm (164 in) |

| Length - Maximum | 4385 mm (172.7 in) |

| Width - Minimum | 1684 mm (66.3 in) |

| Width - Maximum | 2228 mm (87.7 in) |

| Height - Minimum | 2162 mm (85.1 in) |

| Height - Maximum | 2194 mm (86.4 in) |

| Dry Weight - Genset (minimum) | 6668 kg (14700 lb) |

| Dry Weight - Genset (maximum) | 7600 kg (16755 lb) |

Standard Equipment

- Air Inlet System

- Single element canister type with service indicator

- Control Panel

- Warning shutdowns

- EMCP 4.2B

- Digital Indicators

- Communications

- Control features

- Programmable protective relaying functions

- Cooling System

- Caterpillar extended life coolant

- ATAAC

- Coolant drain line with valve

- Low coolant level sensor

- Fan and belt guards

- Radiator fan and fan drive

- Exhaust System

- 203 mm (8 in) ID round flanged outlet

- Exhaust manifold – dry

- Fuel System

- Fuel cooler

- Fuel priming pump

- Secondary fuel filters

- Primary fuel filter with water separator

- General

- RH service

- Caterpillar yellow with high gloss black rails & radiator

- SAE standard rotation

- Flywheel and flywheel housing-SAE

- Generators and Attachments

- Class H temperature rise at 40C ambient

- 3 Phase brushless

- Permanent magnet excitation (PMG)

- Winding temperature detectors

- Integrated voltage regulator (IVR)

- Reactive droop

- IEC standard hole pattern

- NEMA Class H insulation

- Busbar connections, top center mounted, top cable entry

- Salient pole

- 6 Lead

- Internal excitation (IE)

- Governing System

- ADEM(tm) A4

- Lube System

- Gear type lube oil pump

- Oil drain lines and valve

- Fumes disposal

- Lubricating oil

- Integral lube Oil cooler

- Oil filter, filler and dipstick

- Mounting System

- Rubber anti-vibration mounts

- Rails – Engine/generator/radiator mounting

- Power Termination

- Busbar

- Starting and Charging

- 45 Amp Charging alternator

- 24 Volt electric starting motor

- Battery disconnect switch

- Battery, rack and cables

Optional Equipment

- Air Inlet System

- Standard air cleaners

- Heavy duty air cleaner

- Dual element air cleaner

- Circuit breakers

- Shrouds

- 1600, 2000, 2500 and 3200 Amp, 3 Pole, IEC-Rated Circuit breakers

- Center posts busbars

- Enclosures – Control packaging

- 400, 800, 1200, 1600, 2000, 2500 and 3000 Amp, 3 Pole, UL-100% Rated Circuit breakers

- Circuit breaker wiring groups

- Power connection covers

- Cable supports

- 800, 1600, 2000, 2500 and 3200 Amp, 4 Pole, IEC rated Circuit breakers

- Control Panels

- EMCP 4.3, EMCP 4.4

- Cooling System

- High ambient radiator

- Extended life coolant

- Standard radiator

- Radiator duct flange

- Certified radiator

- Enclosures

- Premium sound attenuated enclosure

- Cold weather bundle

- Color options

- DC lighting package

- Sound attenuated enclosure

- AC Panel, outlets and lights

- Panel bracket

- Enclosure fuel tank options

- Enclosure louvers – fixed and motorized

- Exhaust System

- Elbow mounting kit

- Mufflers

- Guard and shield system

- Flange and exhaust expanders

- Flexible fittings

- All C32 engines have 203 mm (8 in) exhaust outlets

- Flanges

- Exhaust through the wall kit

- General

- US aid emblem

- Special paint

- Generator and Attachments

- Medium voltage optional generators

- Low voltage optional generators

- Lube System

- Oil level regulator

- Oil pan

- Prelube manual sump pump

- Mounting System

- Spring type vibration isolators

- IBC vibration isolators

- Mounting base types

- Standard package isolators

- Power Connections

- Center post busbars

- Low voltage connection cables

- Neutral grounding connection

- Power Termination

- Circuit breakers, UL listed

- Circuit breakers, IEC compliant

- Special Tests / Reports

- Standard engine test

- IBC seismic Certifications

- PGS Test report @ 1.0 power factor

- Custom generator TVA report

- Generator test report

- Standard genset Torsional Vibration Analysis (TVA) report

- PGS Test report @ 0.8 power factor

- CSA test and certification

- OSHPD seismic Certifications

- Starting / Charging

- 10 Amp enclosure Battery charger

- 35 Amp Battery charger

- Space heater

- Jacket water heater

- Electric starting motor – Standard/heavy duty

- Heavy duty starting system

- 10 Amp Battery charger

- 20 Amp Battery charger