Enquire about "D6 Dozer" Now

D6 Dozer

Powerful, Reliable, Durable

- Proven Cat® C9.3B engine eliminates Exhaust Gas Recirculation (EGR) system, updated fuel system, and simplification of electronic control modules (ECM) all contribute to a more reliable machine.

- Fully automatic 4-speed transmission continuously adjusts up or down for maximum efficiency and power to the ground without added operator input.

- Redesigned structure, with more weight and horsepower than D6T*, has configurations for you to build the machine for the work you do. Variable Power Angle Tilt (VPAT) tractors with improved range of motion for balanced, high-speed grading or robust Push Arm dozers for heavier applications, larger blades, and optional FirstCut™ cutting edges (SU blades only) for increased payload.

- Heavy Duty Extended Life undercarriage

- HDXL with DuraLink™

- features Positive Pin Retention (PPR2) pins and link improvements for more seal life in high impact conditions. - Cat Abrasion™ undercarriage is a low cost-per-hour solution for high abrasion and low impact jobsites. The design offers double the seal life and eliminates bushing turns, reducing your costs per hour compared to traditional undercarriage. Reduces link scalloping for smoother operation.

- Improved structures for HDXL and Cat Abrasion undercarriage enable changes from one to the other.

- Common sprocket mounting style as other dozers, with segments on the outside of final drive improve serviceability.

- Purpose-built Waste and Forestry/Heavy Duty arrangements.

* Comparison for weight is between the standard configuration operating weights for the D6T and the D6 20C. Horsepower comparison is between the maximum engine horsepower for the D6T at 1,200 rpm and the D6 20C at 1,300 rpm.

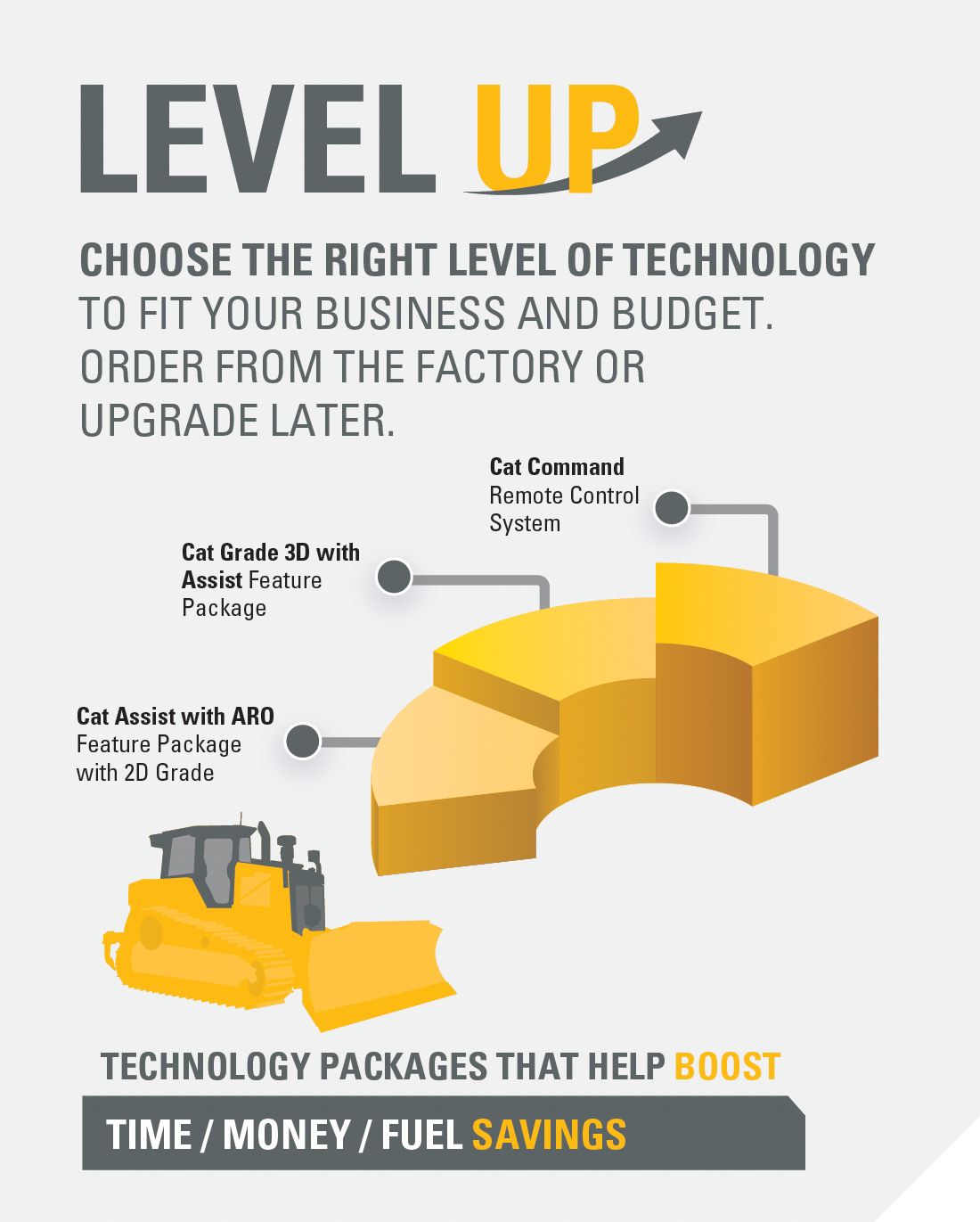

Technology Made Simple

Assist features help make work easier, especially for less experienced operators. Some blade and steering functions are automated so newer operators can work at productivity levels closer to their veteran counterparts. Seasoned operators can enjoy reduced effort and fatigue, along with faster, more accurate results.

- Optional Assist features can reduce operator inputs up to 45%.* Cat Assist with Attachment Ready Option (ARO) features include:

- Attachment Ready Option (ARO) provides wiring and mounting provisions for dealer installation of Grade with 3D, Accugrade, UTS, or other grade control systems.

- Cat Grade with Slope Assist™ automatically maintains pre-established blade position without a GNSS/GPS signal — no additional hardware or software needed. For machines with 3D, operators can easily switch back and forth from full 3D automatics to Slope Assist.

- Steer Assist automates track and blade tilt steering. Helps reduce operator fatigue by automatically maintaining straight travel with light loads or heavy loads on flat ground and side slopes. Helps reduce steering inputs up to 75%. No GNSS/GPS required.

- Stable Blade works seamlessly with operator inputs to help produce a smoother surface when operating manually.

- Slope Indicate is included in the main machine display and shows side slope and uphill/downhill grades to help operators with slope work.

- Blade Load Monitor gives you real-time feedback on current load versus the optimal blade load based on your ground conditions. Actively monitors machine load and track slip to help you reach optimal pushing capacity.**

- Traction Control automatically reduces track slip to save you time, fuel and track wear.**

- AutoCarry™ automates blade lift to help you maintain consistent blade load and reduce track slip.**

- Application Profile lets you save machine settings based on application or operator preference. Utilize any of the default profiles defined by our expert operators or customize profiles for various jobs or multiple operators.

- Operator ID allows you to save custom touchscreen setup, machine settings, and to track individual operator productivity, safety and training opportunities via ProductLink™.

- Machine security

- passcode helps prevent theft and unauthorized operation by requiring an operator to enter an ID to start the machine.

* Input reduction based on product testing of a D5 (17B) Next Generation Dozer with and without the use of Slope Assist in a side slope application. Inputs measured as number of times operator adjusts controls, collected and verified by electronic control module (ECM). Test conducted by Caterpillar at Washington, IL, in July 2022.

** Feature not operational indoors or in areas where GPS signal is not available.

Comfortable Workspace

- Redesigned, Next Generation cab offers commonality across all D5 through D8 dozers, including operator interface, sound reduction, more storage, and adjustable controls.

- Integrated rollover protective structure (ROPS) provides more glass surface area and better visibility.

- Cab options expanded to include Deluxe option. Levels of cab selection give you the ability to select your level of technology readiness and cab comforts and adjustments to suit your requirements.

- Operator adjustments available for 5th to 95th percentile operators to ensure comfort.

- Full-color 254 mm (10-inch) touchscreen display has an easy-to-use operator interface. Location of this display can be swapped with the Grade Control display. Viscous cab mounts reduce vibration for greater operator comfort.

- Wider air suspension seat has multiple adjustments for personalized comfort.

- Entire armrest adjusts forward and backward independent of the seat.

- Detented thumbwheel on the steering control allows easy speed setting changes.

- Ample storage spaces throughout the cab.

- Distributed cab heating/cooling circulates air more effectively around the operator and helps reduce window fogging/frosting.

Built-In Safety, Easy Maintenance

- Integrated ROPS and hood design, with alignment of the exhaust and precleaner, provide a better view of the front of the tractor and overall added visibility.

- Standard, integrated High Definition (HD) rearview camera in the primary display.

- The ladder at the back of the machine is standard for convenient access for fuel fill, window cleaning, and maintenance.

- Ground-level access to optional fast fuel fill, grab rails on both sides of cab roof, and tie offs provide added safety.

- Improved cab filtration for cleaner operator environment.

- Standard light package features 4 LED lights with the option to upgrade to 8

- or 12-light packages and other optional, integrated LED warning lights. - Bluetooth microphone gives you hands-free access to your mobile phone.

- Newer design reduces maintenance cost due to updated components, longer service intervals, fewer scheduled maintenance tasks.

- Grouped service points, modular components with easy access, and fewer filters save you routine maintenance time.

- Cab air filter replacement extended to 500 hours.

- Standard reversing fan extends the time between core clean-outs.

- 30-minute cab removal, for easy access to maintenance points, if needed.

- Modular, self-contained HVAC unit is easier to service.

More Productivity With Cat® Technology

Top Grades

- Factory integrated Cat Grade with 3D uses GNSS/GPS to control the blade so you can get to design plan faster.

- Cat Grade with 3D has no masts

- low profile antennas are integrated into the cab roof and GNSS/GPS receivers are mounted inside the cab for better protection. - Automatically follow guidance lines from design plans with Steer Assist 3D. Stay on curb lines, centerlines, bottom of slope, etc., without operator effort. Track steering is used under light loads and blade tilt steering may be added under heavy loads.

- Grade operator interface is intuitive and easier to use: 10-inch (254 mm) touchscreen, Android OS platform, operates like a smart phone.

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica. Already invested in a grade infrastructure? The cab is Third Party Grade Control Ready, equipped with CAN interface, harness pass throughs and mounting features to make it easier to install the grade control system of your choice.

Remote Control Ready

- Cab is Remote Control Ready from the factory with external connector for dealer installation of the Cat Command system.

- Cat Command remote control technology provides full dozer maneuverability from a safe distance when working in hazardous environments.

- Command offers the choice of line-of-sight consoles or long-distance operator stations (non-line-of-sight).

- Take advantage of the dozer’s Grade and Assist features while out of the cab using the Command Station or Console.*

*Not all technology features are available on the Command Console. Please consult your Cat dealer for feature availability by dozer model.

Configuration Options

Waste Handling

- Specialized guarding and seals throughout the machine help protect major components from impact and airborne debris.

- Waste cab has impact-resistant polycarbonate doors, eliminating the need for door screens.

- Larger capacity landfill blades, front and rear striker bars, and center-hole track shoes optimize the machine for waste handling applications.

- Multi-layer final drive guards, including a labyrinth-style guard with 90-degree turns, help keep dirt and debris away from the Duo-Cone™ seal to protect final drive oil.

- Tilt cylinder with rotating bushing type design help wrapping materials to roll off hoses.

- Heavy-duty, hinged radiator guard protects radiator and fan from penetration by material coming straight in or from under the blade.

- Cooling system designed for high debris environments, with automatic reversing fan and swing-out cleanout access.

- Powered precleaner is integrated and increases the cab filter change interval to 1,000 hours.

- Laminated thermal shields and insulated Clean Emissions Module.

- Bottom guard, chassis and tilt cylinder guards, and guarding over the fuel tank and battery box for extra protection from debris.

Heavy Duty/Forestry

- Forestry cab with impact-resistant, polycarbonate doors for added safeguard without the use of door screens. Side and rear screens can help further protect the operator and machine from debris. Hinged screens provide easy access to windows for cleaning and maintenance.

- Closed sweeps provide more protection for the operator and machine with an enclosed canopy over the cab to protect the top of the machine while allowing upward visibility. Optional open sweeps can be used for applications where a canopy is not preferred.

- High debris seals offer additional protection around fenders, fuel tank, radiator guard and rear hood support. Provides a seal across the top, rear of the case to prevent debris entry.

- Single plane cooling system with automatic reversing fan aids cleanout. High debris engine air filtration system extends filter life.

- Heavy duty bottom guards and fuel tank guard help shield major machine components. Sealed bottom guards available on push arm machines.

- Heavy Duty Extended Life (HDXL) undercarriage. Track bushings can be turned and re-sealed mid-life. Press-fit bushings and PPR2 pin retention are particularly well suited for impact applications like forestry.

- Premium light package with 12 LED lights with light guards provide 360-degree light coverage.

| Engine | |

|---|---|

| Engine Model | Cat® C9.3B |

| Power - Net | 161 kW (215 hp) |

| Net Power - Rated - ISO 9249/SAE J1349 | 161 kW (215 hp) |

| Net Power (Rated) - ISO 9249 (DIN) | 219 mhp (219 mhp) |

| Build Number | 20C |

| Emissions | Brazil MAR-1 and UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/EU Stage IIIA |

| Note (1) | Rated horsepower at 2,200 rpm. Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture. |

| Note (2) | Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or u201cCaterpillar Machine Fluids Recommendationsu201d (SEBU6250) for details. ** Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). |

| Weights | |

|---|---|

| Operating Weight | 22130 kg (48788 lb) |

| Transmission | |

|---|---|

| Powertrain | Fully Automatic 4-speed Powershift Transmission with Lock Up Clutch (LUC) |

| Service Refill Capacities | |

|---|---|

| Fuel Tank | 341 l (90 gal (US)) |

| D6 Push Arm | |

|---|---|

| Operating Weight | 22130 kg (48788 lb) |

| Ground Pressure | 54 kPa (7.9 psi) |

| Width of Standard Shoe | 610 mm (24 in) |

| Blade | Semi-Universal (SU) |

| Blade Capacity | 5.7 mu00b3 (7.5 ydu00b3) |

| D6 LGP (36-in) Push Arm | |

|---|---|

| Operating Weight | 23911 kg (52715 lb) |

| Ground Pressure | 36 kPa (5.2 psi) |

| Width of Standard Shoe | 915 mm (36 in) |

| Blade | Straight |

| Blade Capacity | 3.8 mu00b3 (5 ydu00b3) |

| D6 VPAT | |

|---|---|

| Operating Weight | 22275 kg (49108 lb) |

| Ground Pressure | 49 kPa (7.1 psi) |

| Width of Standard Shoe | 610 mm (24 in) |

| Blade | VPAT |

| Blade Capacity | 4.1 mu00b3 (5.4 ydu00b3) |

| D6 LGP (30-in) VPAT | |

|---|---|

| Operating Weight | 23012 kg (50733 lb) |

| Ground Pressure | 40 kPa (5.9 psi) |

| Width of Standard Shoe | 760 mm (30 in) |

| Blade | VPAT |

| Blade Capacity | 4.5 mu00b3 (5.9 ydu00b3) |

| D6 LGP (36-in) VPAT | |

|---|---|

| Operating Weight | 23547 kg (51912 lb) |

| Ground Pressure | 34 kPa (5 psi) |

| Width of Standard Shoe | 915 mm (36 in) |

| Blade | VPAT |

| Blade Capacity | 4.9 mu00b3 (6.5 ydu00b3) |

| Air Conditioning System | |

|---|---|

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. - If equipped with R134a (Global Warming Potential = 1430), the system contains 1.36 kg (3.0 lb) of refrigerant which has a CO2 equivalent of 1.95 metric tonnes (2.14 tons). |

Standard Equipment

- Note

- Standard and optional equipment may vary. Consult your Cat® dealer for details.

- Powertrain

- Cat® C9.3B engine

- Differential steering system

- Fully automatic 4-speed transmission with Lock Up Clutch (LUC) torque divider

- Engine air pre-cleaner with dust ejection

- Double reduction planetary final drives

- Automatic ether starting aid

- Electric fuel priming pump

- Electronic parking brake

- Engine air filter with electronic service indicator

- Fuel water separator with electronic service indicator

- Jacket water heater, 110V OR 220V based on sales region

- Cat Technology

- Slope Indicate

- Third Party Grade Control Ready Cab

- Compatibility with radios and base stations from Trimble, Topcon, and Leica

- Capability to install 3D grade systems from Trimble, Topcon, and Leica

- Product Link – cellular

- Remote Flash/Troubleshoot

- Operator ID

- Machine security – passcode

- Remote Control Ready

- Operator Environment

- Fully redesigned Premium cab with integrated ROPS and FOPS, single pane door glass, sliding windows, with Cat Advanced Cabin Filtration

- Gauge Cluster

- Integrated rearview camera

- Adjustable operator controls/armrests

- Cloth seat with mechanical adjustable lumbar support

- Cab mounted modular HVAC system with automatic reversing fans. Automatic temperature and blower control with distributed ducting.

- Viscous cab mounts for improved ride

- USB and Auxiliary ports

- Enhanced cab storage solutions

- Adjustable foot pegs

- Screen ready, side and rear

- Operator presence switch

- Undercarriage

- Structurally improved track roller frame designed to allow conversion between HDXL and Abrasion

- Undercarriage with 8 bottom rollers

- Heavy Duty (HDXL with DuraLink™)

- Moderate service track shoes

- Carrier roller

- Hydraulically adjustable track

- Hydraulics

- Load sensing hydraulics – dozer lift and tilt

- Independent steering hydraulics

- Ripper ready rear hydraulics

- Single axis ripper control

- Hydraulic automatically reversing, zero speed capable cooling fan

- Electronic hydraulic lockout switch

- Electrical

- Standard Lights – 4 LED light package

- Backup alarm

- Converter: 15 Amp, 12V outlet

- Diagnostic connector

- Forward warning horn

- Fuse panel and main power relay located inside cab

- Service and Maintenance

- Ecology drains

- Ground level service center with remote electrical disconnect, access light, and secondary shutdown switch

- Fuel tank, 341 L (90 gal)

- Mounting provisions for grease gun, shovel, and fire extinguisher

- Perforated radiator doors, louvered and hinged

- Rear access ladder

- Removable engine enclosures, perforated and hinged, with under hood work light

- Scheduled Oil Sampling (S·O·S℠) ports

- Maintenance free equalizer bar

- Certified ISO 14567 tie off points (3)

- Vandalism protection for fluid compartments and battery box

- Dedicated shipping tie downs, rear

- Batteries, Starters, Alternators, and Fluids

- 95 Amp alternator

- Heavy duty, 24V starter

- Extended Life Engine coolant, –37° C (–35° F)

- Attachments

- Drawbar

- Guarding and Screens

- Hinged bottom guards

- Standard duty grab handles

Optional Equipment

- Note

- Standard and optional equipment may vary. Consult your Cat® dealer for details.

- Powertrain

- Engine air pre-cleaner with dust ejection and screen for high debris applications

- Double reduction planetary final drives, guarded

- Cat Technology

- Cat Assist with ARO package

- Cat Grade 3D Ready with Assist package (hardware only)

- Cat Grade 3D with Assist package

- Product Link – dual cellular/satellite

- Grade connectivity

- Machine security – Bluetooth®

- Cat Command for Dozing

- Operator Environment

- High debris cab, fully redesigned with integrated ROPS and FOPS, impact resistant polycarbonate doors, solid side windows for improved sealing, powered pre-cleaner with Cat Advanced Cabin Filtration for improved performance and filter life

- Fully redesigned heavy duty cab with integrated ROPS and FOPS, impact resistant polycarbonate doors, sliding windows, with Cat Advanced Cabin Filtration

- Full-color 254 mm (10 inch) liquid crystal touchscreen display

- Joystick control – ARO

- Deluxe leather heated/ventilated seat with electronic adjustable lumbar support

- Cat Advanced Cabin Filtration with powered pre-cleaner with MERV 16, HEPA, and Activated Charcoal options

- Entertainment radio with Bluetooth and microphone

- Quick opening floor plate

- Undercarriage

- Undercarriage with 10 bottom rollers for fine grading applications

- Waste undercarriage (HDXL only)

- Partially guided undercarriage

- Fully guided undercarriage

- Cat Abrasion™ track

- Extreme service track shoes

- Replaceable sprocket rim segments

- Blades

- Semi-Universal, ARO mounts

- Semi-Universal, LGP with ARO mounts

- Semi-Universal, Waste

- Semi-Universal, LGP Waste

- Straight blade, LGP with ARO mounts

- Straight blade, LGP Waste

- VPAT, ARO mounts

- VPAT, LGP with ARO mounts

- Cat FirstCut™ cutting edges (SU blades)

- Hydraulics

- Ripper and winch ready rear hydraulics

- Dual axis ripper/winch control

- Electrical

- Optional Lights – 6 LED light package

- Premium Lights – 12 LED light package

- Integrated beacon warning light (does not impact shipping height)

- Communication radio ready kit

- Service and Maintenance

- 30-minute cab removal

- Ecology drains with high speed oil power train and engine oil change

- Hour meter

- Fuel tank, 341 L (90 gal), fast fill ready

- Wiggins style fast fill nozzle

- Rear work light

- Batteries, Starters, Alternators, and Fluids

- 150 Amp alternator

- 150 Amp ducted alternator

- Heavy duty batteries, two maintenance-free 12V (1,400 CCA) (24V system)

- Extended Life Arctic engine coolant, –51° C (–60° F)

- Attachments

- High lift multi-shank ripper with straight or curved shanks

- Lightweight rear tow point

- Striker bar box

- Counterweights (not recommended unless using heavier aftermarket blades)

- PACCAR PA56 winch, low speed PTO

- PACCAR PA85 winch, variable speed hydraulic

- PACCAR PA56 winch, standard speed PTO (Dealer only)

- Allied H6H winch, variable speed hydraulic (Dealer only)

- Fairlead Assembly; 3-roller, fits PA55, PA56, and PA85 winches

- Retrofit kit (4th roller); fits PA55, PA56, and PA85 winches

- Guarding and Screens

- Heavy duty sealed and hinged bottom guards (Push Arm only)

- Heavy duty sealed quick access hinged bottom guards (Push Arm only)

- Heavy duty grab handles

- Open Sweeps guarding

- Forestry Sweeps guarding with full canopy

- Hinged rear screen

- Hinged side screens

- Fuel tank guard (with or without fast fill)

- Guards for premium lights, front and side

- Machine seals for high debris

- Front and rear striker bars (Push Arm only)