Enquire about "AP300 Asphalt Paver" Now

AP300 Asphalt Paver

High Quality Results, Higher Earnings

- Standard paving range of 1.75 m

- 3.2 m (5′ 9″

- 11′ 2″) with a maximum width of 4 m (13′ 1″) deliver excellent performance for parking lots, urban streets, pathways, trenches, narrow shoulders, and other mid-sized applications - An optional paving reduction attachment narrows the paving width to 700 mm (27.5″)

- Heated end gates, variable frequency vibration, and tamper bar settings help provide smooth material flow

Technology That Works for You

- Exclusive Eco-mode and automatic engine speed control, reduce fuel consumption and lower sound levels for better comfort and communication

- Auto-fill feeder system simplifies setup by filling the auger chamber to the set point determined by the feed sensors

- Single touch feeder system activation optimizes efficiency by activating each auger and each conveyor

- Automated travel feature; augers raise with the screed, preventing damage during transport

- Single-touch hopper control enables operators to concentrate on other duties

Low Owning and Operating Costs

- Engine options available to meet U.S. EPA Tier 4 Final, EU Stage V emissions and other regional standards

- Million cycle switches provide reliability

- Conveyor bed plates and chain guards designed to minimize labor requirements and provide lower cost replacement

- Heating elements slide out for easy replacement

- Machined screed frames simplify screed plate leveling

Unmatched After-The-Sale Support

- Strategically located dealers with 24/7 support

- In-the-Iron service training for technicians

- Paver Operator Training helps maximize machine performance

- Project consulting helps improve technique and job site management

More Comfort

- Ventilation system option draws fumes from the auger chamber and redirects them away from the operator for a more comfortable working environment

- Single sliding console enables operation from either side of the machine

- Dual independent seats swing out beyond the platform for good visibility to curbs and obstacles

- Heated seat option delivers comfort in cool weather conditions

- High visibility 76 mm (3″) seat belt helps with crew safety compliance

Easy Viewing Displays, Simple Operation

- Operating displays can be tailored to specific language requirements with multiple options available

- Easy access to generator activation, screed temperature control, screed heating zones, tamper and vibratory speeds, and service code information

- Intuitive symbols and large graphics simplify operation

- Adjustable brightness control for easy viewing day or night

- Raised switch design enables easy recognition for better efficiency and performance

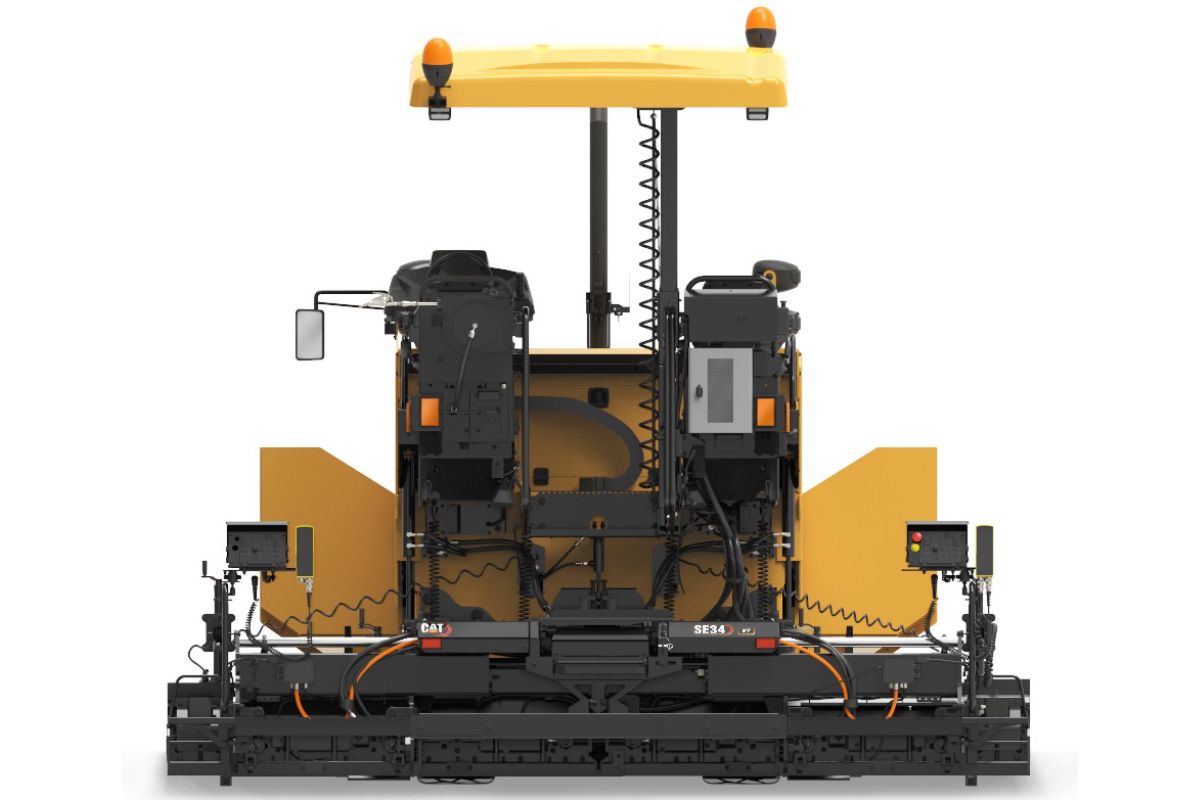

Screeds That Deliver Quality

- SE34 V and SE34 VT screeds deliver excellent ride, density, and mat texture while providing superior adjustment capabilities

- Basic Grade Control option available

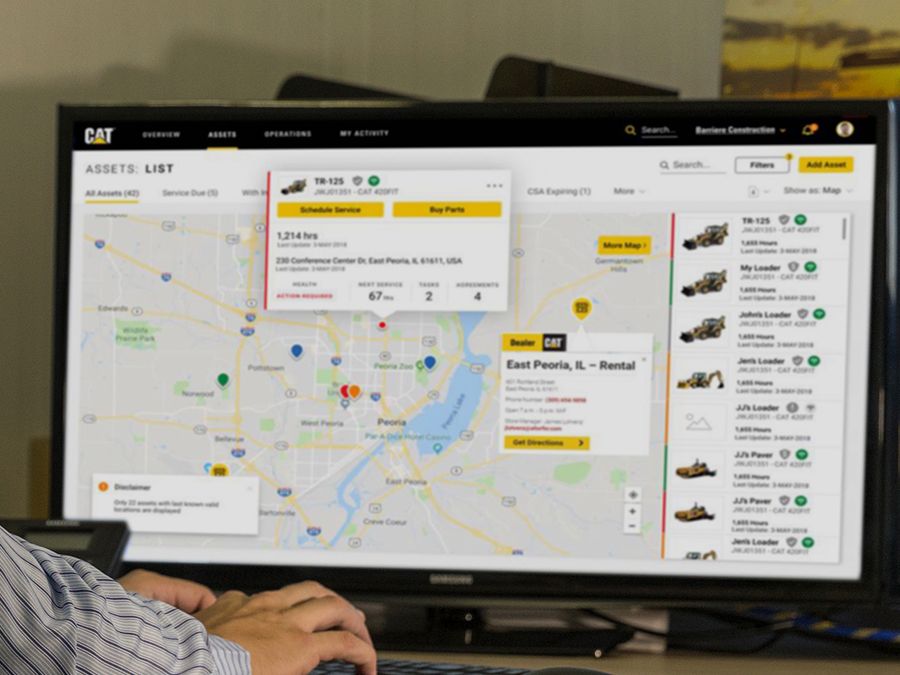

Product Link™ Elite

- Make timely, fact-based decisions to maximize efficiency, improve productivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time in real time

- Diagnostic codes are made available through online web applications

- Scheduled maintenance and Scheduled Oil Sampling notification

Service and Repair Kits

- Paver and screed service and repair kits include all the parts necessary to complete specific repairs

- Cat genuine parts are manufactured to precise specifications and designed for optimal performane and maximum uptime

- Repair kits are identified by a single part number to make ordering easy

- Select kits are available to be packaged as a kit by the dealer for over-the-counter purchases or through the dealer service shop

Standard Equipment

- Operating Environment

- Single sliding console

- Steering guide

- Technology

- Product Link™ Elite 6412 (cellular)

- Powertrain

- Cat® C3.3B, four-cylinder

- Cooling fan, variable speed

- Radial drive Tires

- Electrical System

- 750 CCA battery, maintenance-free

- 85-amp alternator

- 12-volt charging system

- Automotive-type fuse system

- Cat® Electronic Technician (Cat ET)

- Material Delivery

- Material feed sensors, contact

- Push-roller, adjustable

- Service and Maintenance

- Hydraulic oil, Cat HYDO™ Advanced

- Remote access drains

- Service repair kits

- Sampling ports for Scheduled Oil Sampling

- Sight Gauges, engine coolant, hydraulic oil

- Safety

- Alarm, back-up

- Horn, warning (front & rear)

- Lights, LED Working

- Mirror package

Optional Equipment

- Operating Environment

- Canopy

- Deceleration pedal

- Umbrella

- Ventilation system

- Technology

- Basic Grade Control

- Product Link™ 631 Satellite

- Powertrain

- Ballast, front weights

- Front-wheel assist

- Material Delivery

- Material feed sensors, sonic

- Wash-down pump and reel

- Service and Maintenance

- Bio-hydraulic oil