Enquire about "6060 Hydraulic Shovel" Now

6060 Hydraulic Shovel

SAFETY

- Excellent visibility thanks to cab position that provides clear view to the digging and loading areas, floor window that provides a view to the tracks, LED lighting, and optional camera monitoring system.

- Emergency egress ladder with a self-closing door located in direct proximity to the cab.

- Safer access with 45-degree powered access stairway that features emergency lowering via a nitrogen accumulator, which ensures it remains operational even when engines shut off.

- Safer electrical and/or mechanical maintenance thanks to lockable starter and battery isolation switch cabinet.

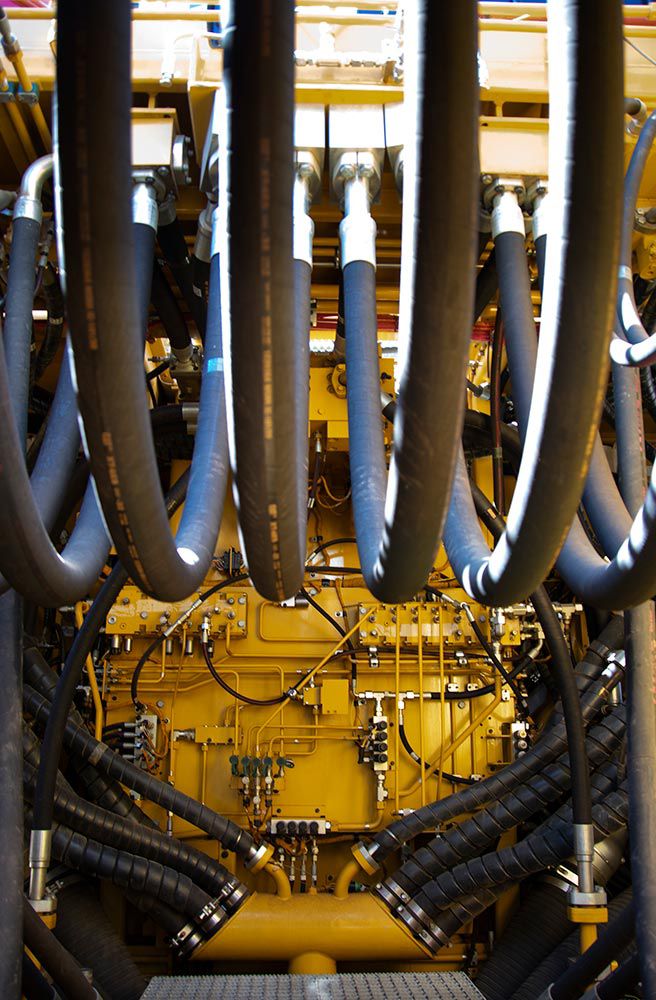

- Safer service with improved sealing between engines and hydraulic pumps, improved routing and separation of hydraulic lines and electric cables.

OPERATOR CAB

- Improved operator comfort with Cat Next Gen heated and cooled seat and integrated joysticks.

- First-in-class and patented 3-seat design, including elevated full-size trainer’s seat and laptop work desk.

- New and improved air conditioning system.

- Reduced noise and temperature control thanks to superior insulation.

- Productivity-boosting Operator Assist

- Enhanced Motion Control, which reduces fatigue and helps inexperienced operators more confidently load material.

RELIABILITY & DURABILITY

- Improved structures, including increased weight, strengthened superstructure and increased thickness in several locations.

- 33% longer service life for new and enlarged slew ring.

- New undercarriage with long-life components, frame and electronics.

- New crawler frame and Cat undercarriage with HD rollers, HD idlers, HD track, and track tensioning.

- New and improved engine design that improves reliability and extends gallons consumed before first overhaul by 10%, which also contributes to longer engine life.

PRODUCTIVITY & PERFORMANCE

- Up to 15% greater efficiency through Hydraulic Optimization, which dynamically assigns individual pumps or groups of pumps to deliver the exact flow and pressure that each hydraulic function requires.

- Faster cycle times and improved energy efficiency delivered by closed-loop swing system, which also generates less heat.

- Greater operator control thanks to five circuit hydraulics that allow for two cylinder motions, two travel motions, and swing to be controlled simultaneously.

- Easier and faster face shovel operation with unique TriPower face shovel design, which generates superior mechanical leverage and control.

- Increased productivity and greater uptime with the twin engine concept, which enables up to 65% of full production with a single engine.

BUCKETS & GET

- Buckets and ground engaging tools (GET) designed to maximize durability and productivity and ideally matched to your shovel and application.

- Integrated to work as part of a machine system — helping you achieve high productivity and the lowest cost per ton.

- Variety of sizes and material densities for the ideal match to your shovel and application.

- Deliver optimal payload when combined with Cat GET and wear components.

- Wear packages that protect your investment, including special liner material and lip shroud, wing shrouds and heel shrouds.

CONNECTIVITY & TECHNOLOGY

- Greater connectivity with improved Product Link™ Elite system, which increases the availability of data provided by the 6060.

- Additional performance and reliability advantages through integration of proven and validated Cat electronics.

- Intuitive, informative onboard electronics that help operators be more productive.

- Enhanced diagnostic capabilities and troubleshooting functions with factory-installed Monitoring and Diagnostic System.

- Connectivity features and the integration of Cat MineStar™ Health offerings enable a proactive approach to maintenance.

SERVICEABILITY

- More room in the service compartment, plus easy access to slew gearboxes, rotary distributor, oil cooler and more.

- Clear arrangement of components on the superstructure for easy access and serviceability.

- Hose assemblies that can be built locally using all Cat material.

- Access to Cat Electronic Technician, which helps dealer service personnel more easily diagnose and prevent issues.

- Reduced maintenance downtime thanks to exchange intervals for engine oil and engine filters that have been increased from 500 to 1,000 hours

SUSTAINABILITY

- Reduced fuel burn thanks to 10% improvement in hydraulic efficiency.

- Reduced emissions with engines that satisfy Tier 4 standards and eliminate the need for Diesel Exhaust Fluid (DEF) — saving time and cost during maintenance.

- Less heat and improved efficiency with the closed-loop swing circuit.

- Reduced owning and operating costs thanks to increased commonality of systems and components, plus a reduction in unique part numbers.

- Preservation of raw materials, energy conservation and reduced emissions through the Cat Reman program, which returns end-of-life components to like-new condition.

Standard Equipment

- 2 x Cat 3512E engines

- Cat Powertrain

- Aftertreatment System (used in highly regulated countries only): -Diesel Oxidation Catalysts (DOCs) -Non-DEF solution

- Air-to-Air After Cooling (ATAAC)

- Turbocharger

- Hydraulically driven radiator fan

- Electronically controlled fan speed

- Micro processed engine management

- Heavy-duty air filters

- Two-stage fuel filter with series filtration

- High-capacity water seperator

- Starting aid — automatic ether

- Exhaust manifold and turbo heat shields

- Dual 24 V electric starters per engine

- Automatic engine idle shut down

- Automatic fuel priming

- Hydraulics

- Hydraulic Optimization

- Operator Assist: Enhanced Motion Control

- Cat Hydraulic Hose assemblies

- Pump managing system with: -Electronic load limit control -Flow on demand -Automatic zero flow regulation -Automatic engine rpm reduction -Reduced oil flow at high hydraulic oil or engine temperature

- Pressure cut-off for main pumps

- Cooling of pump transmission gear oil

- Closed loop swing circuit

- Pressure testing points

- Full-flow high-pressure filters (100 μm), main pumps

- High pressure filters (100 μm), closed swing circuit

- Full-flow filters (10 μm), return circuit

- Pressure filters swing charge circuit (40 μm)

- Pressure filters pilot circuit (6 μm)

- Transmission oil filters (40 μm)

- Boom float valve (FS and BH)

- Stick float valve (FS)

- Electrical System

- 6 Maintenance-free batteries

- Lockable battery isolator switch

- Lockable starter isolator switch

- 13 LED high-brightness working flood lights

- 17 LED service lights

- 2 acoustic travel alarms -forward and reverse (power module, oil cooler module)

- 2 electric horns (1 cab module, 1 oil cooler module)

- Undercarriage

- HD tracks with cast double-grouser track pads

- 1400 mm (4’7″) wide track pads

- HD fixed axle carrier and load rollers

- HD fixed axle idlers

- Automatic hydraulic retarder valve

- Hinged travel motor covers

- Hardened running surfaces of sprockets, idlers, rollers, pad links, teeth contact areas

- Fully hydraulic self-adjusting track tensioning system with piston accumulators

- Automatic Lubrication System

- Rectangular grease container (fill via service station)

- Lubricated pinion in swing ring

- Grease filters (200 μm)

- Operator Environment

- Single hydraulically driven HVAC system

- In-floor window with removable grate

- Pneumatically cushioned and multiadjustable comfort seat with: -Heating and cooling -Lumbar support -2-point safety belt -Head and arm rests -Safety switch for automatic motion shutdown

- Independently adjustable seat consoles with integrated joysticks

- Electronic-Hydraulic Servo Control

- Elevated full-size trainer seat with 2-point safety belt and laptop desk

- Additional fold-away auxiliary seat with 2-point safety belt

- Three cup holders

- FM/AM radio with USB and AUX input

- Parallel intermittent wiper/washer

- Roller blinds

- Monitoring system with 254 mm (10 in) color touchscreen

- 45° stairway from engine bay to operator cab

- Powered 45° access stairway

- Heated mirror on LH side

- Camera monitoring system (Right and rear cameras, 2 lights, and additional display)

- Level indicators for length and crosswise inclination

- Document Storage

- Front Attachment

- Service access holes from both sides in boom and stick (FS and BH)

- Boom and stick thermally stress relieved after welding

- Catwalks with rails at boom (FS and BH)

- Wear Package (as per bucket selection)

- Cat Technology

- Cat Product Link™ Elite (Cellular)

- Cat MineStar™ Solutions Ready

- Service and Maintenance

- Engine oil exchange interval — 500 hours

- Hydraulic oil change interval -10,000 hours

- Scheduled Oil Sampling (S·O·SSM) ports

- Retractable ground level service station with quick couplings for: -Diesel fuel -Engine coolant -left/right engines -Pump transmission gear oil -left/right engines -Engine oil -left/right engines -Engine oil extension tanks -Hydraulic oil -Grease -Swing transmission gear oil

- Cat battery charging connector

- Indicator lights

- Cat Electronic Technician service port

- Dirt wiper at swivel

- Safety and Security

- Emergency stop switches: 2 in cab, 5 in engine module, 1 at ground level service station, 1 pull rope accessible from ground level

- Operator Protective Guard (Top Guard)

- All-round safety glass

- Emergency egress ladder

- Maintenance

- ISO or ANSI decals

Optional Equipment

- GENERAL

- Custom paint

- SUPERSTRUCTURE

- Oil change interval extension for engine oil up to 500 hours, with optional extension to 1,000 hours

- Rectangular grease container, 710 L (188 gal), filled via service station

- Various cold-weather options for temperatures below -10°; 400 V, 50 Hz and 208 V, 60 Hz

- CAB

- Dual hydraulically driven HVAC system for redundancy

- Cab heating

- Camera monitoring system with two cameras, two lights, and additional display

- UNDERCARRIAGE

- Track pad width 1400 mm (4 ft 7 in)

- Belly plate for undercarriage protection

- Additional optional equipment available on request.