Enquire about "1765 mm (70 in) Ripper / Scarifier" Now

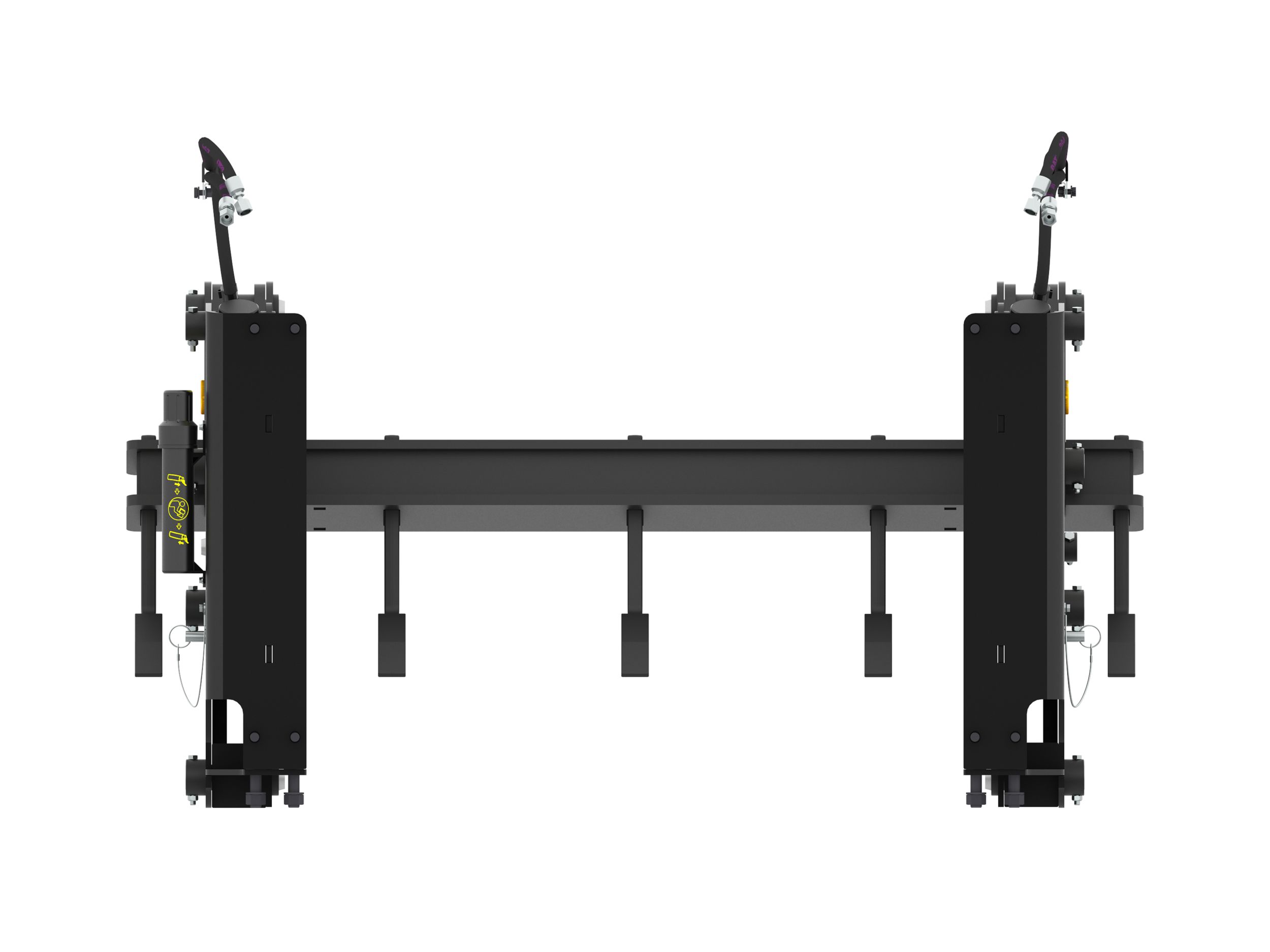

1765 mm (70 in) Ripper / Scarifier

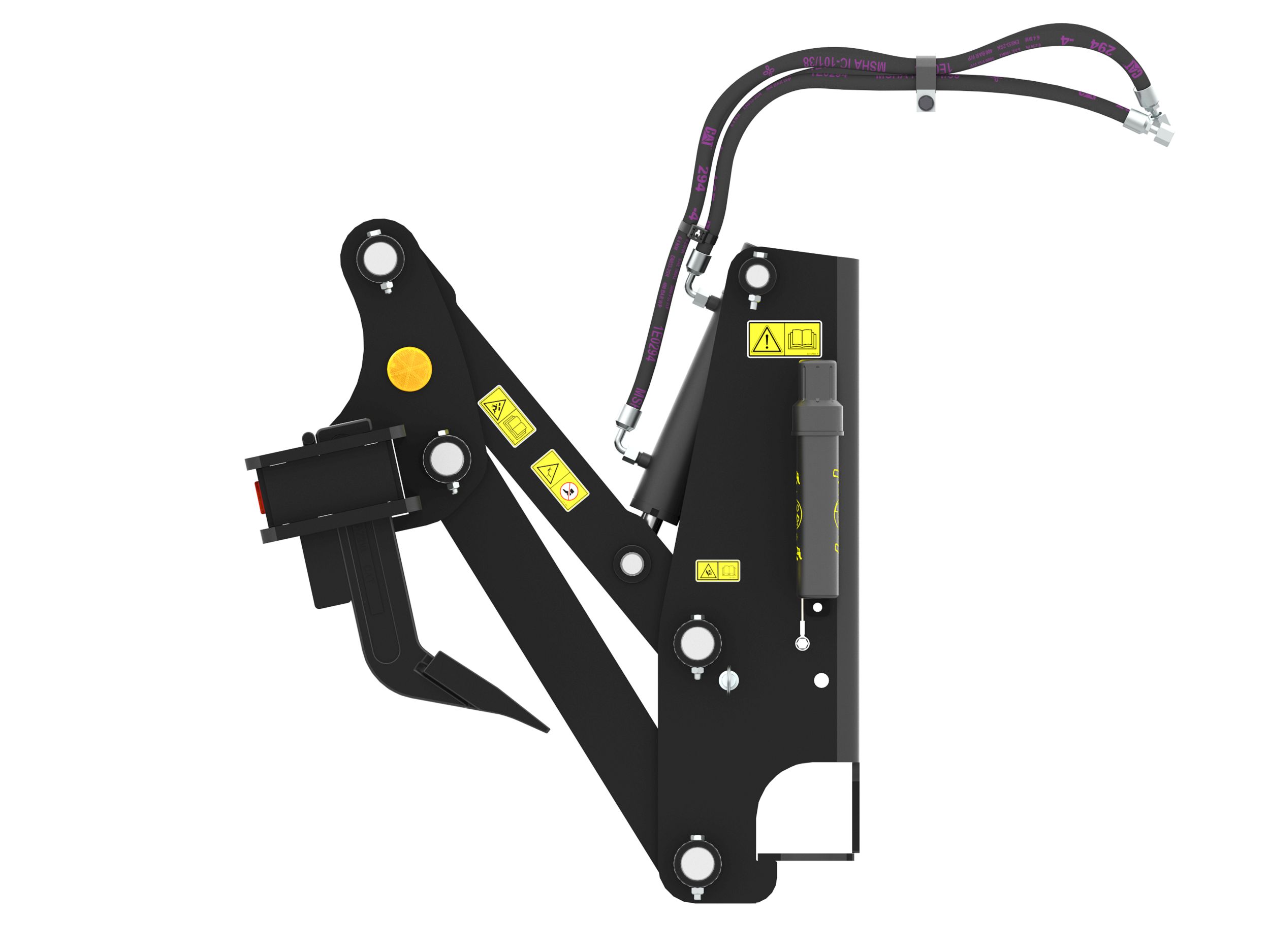

Unique Linkage

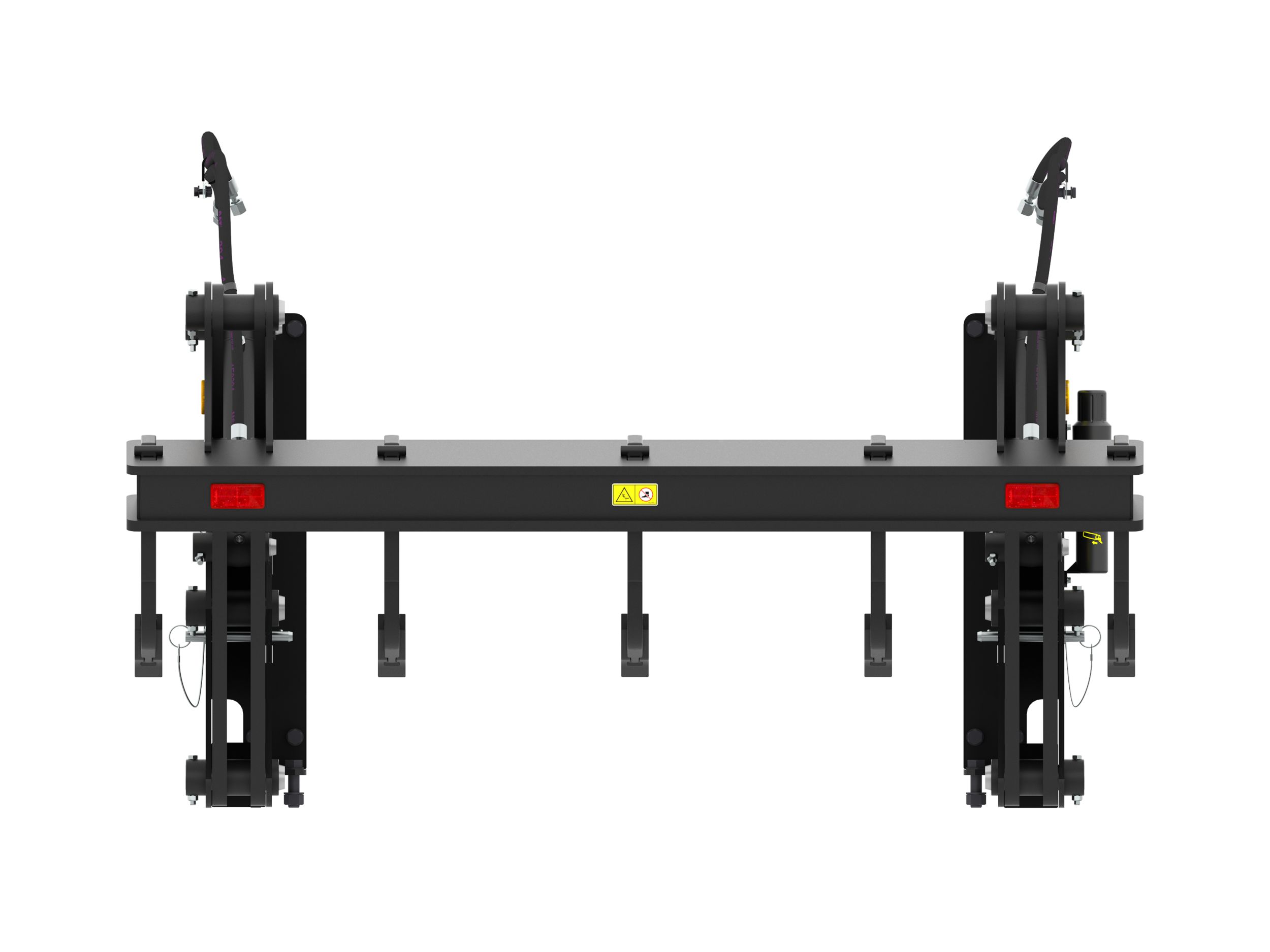

Unique parallelogram linkage design (patent pending) allows shanks/teeth to rotate inward when raised to maximize machine departure angle.

Proven Shank and Tooth Design

Utilizes the same robust shank and tooth design proven tough on Cat® motor graders. Multi-shank design allows operator to select the number of shanks necessary for each application. Shanks and teeth are removeable and replaceable.

Dedicated Operational Control

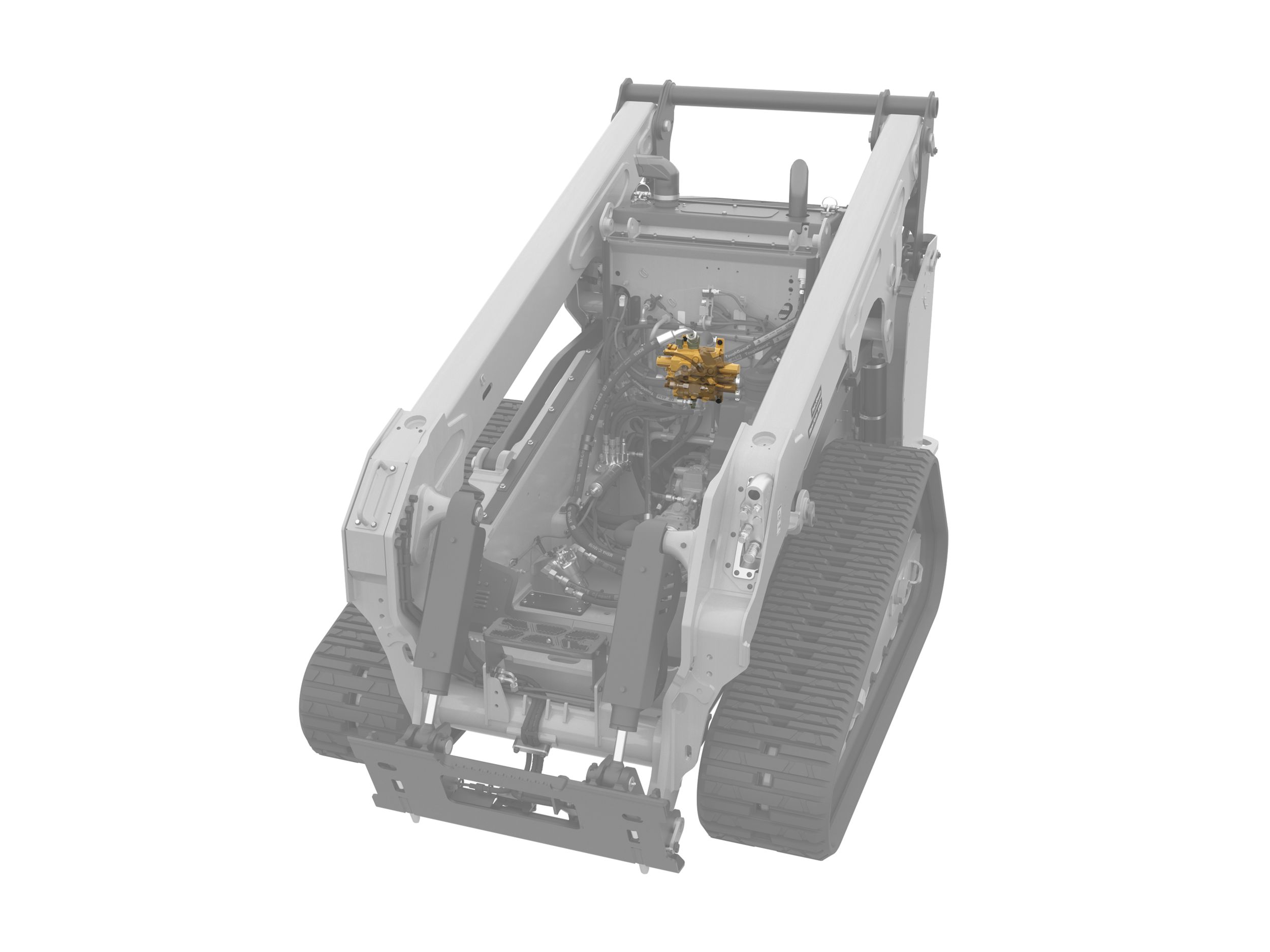

The ripper/Scarifier requires optional machine rear auxiliary hydraulics, available from factory or as a dealer installed kit. Control is Integrated with the advanced joystick controls (Aux 9 / Aux 10).

Adjustable Rear Hydraulic Flow

Raise/lower speed may be adjusted via flow control valves based on operator preference.

Full Service Access

In the lowered position, the engine bay door is unobstructed for easy access and daily service tasks.

Transportation Configuration

Scarifier shanks can be reoriented in ripper frame for increased machine departure angle while trailer loading machine. Two lock-out pins retain the ripper linkage in the fully raised position to prevent hydraulic cylinder drift during transport.

OMM Container

Tool mounted and sealed from the elements, this holder includes all the operation manuals and maintenance guides required for proper operation of the tool.

Dead Engine Lowering Capability

Special key function would allow the ripper / scarifier to be lowered to a position that allows easy engine bay access if the engine and/or battery are dead.

| Product Specifications | |

|---|---|

| Overall Width | 1765 mm (69.5 in) |

| Length | 1115 mm (43.9 in) |

| Height | 1373 mm (54.1 in) |

| Shank Spacing | 374 mm (14.7 in) |

| Weight | 451 kg (994.3 lb) |

| Optimal Hydraulic Pressure | 24100 kPa (3495.4 psi) |

| Optimal Hydraulic Flow | 13 L/min (3.4 gpm) |

| Cycle Time | 2.5 seconds |